Read about how Tiffany & Co. employed the metalworking technique of patinating copper with illustrative artworks and process demonstrations, or watch the video below.

Patinas are thin, colored layers on the surface of metals. Exposure to air and humidity over time is often enough to create an oxide layer on many metals, like the green on copper roofs. However, many artisans control the development of that layer, usually through chemical patination solutions or the application of heat.

Left: Tiffany & Co. (American, 1837–present). Chocolate Pot , 1879. Silver, patinated copper, gold, and ivory, 11 5/8 x 7 x 5 1/2 in. (29.5 x 17.8 x 14 cm). The Metropolitan Museum of Art, New York, Purchase, Louis and Virginia Clemente Foundation Inc. and Emma and Jay A. Lewis Gifts, 2017 (2017.156a, b) | Right: Tiffany & Co. (American, 1837–present). Mustard Pot, ca. 1879. Silver, copper, gold, patinated copper-gold alloy, patinated copper-platinum-iron alloy, and niello, 3 1/8 x 2 1/2 x 2 in. (8.1 x 6.4 x 5.1 cm). The Metropolitan Museum of Art, New York, Purchase, Friends of the American Wing Fund and Emma and Jay A. Lewis Gift, 2016 (2016.689)

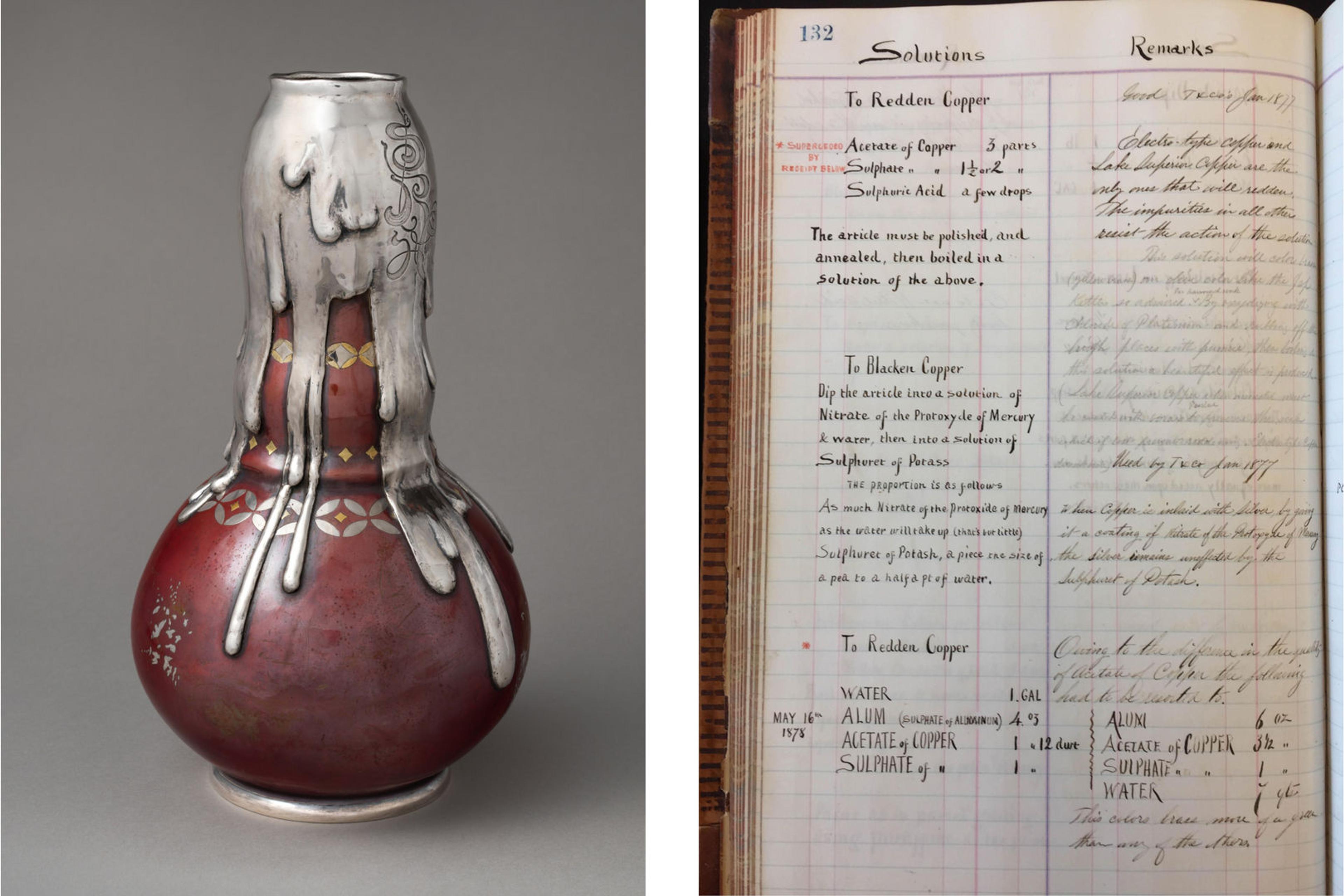

Tiffany & Co. craftspeople incorporated patinated metals extensively into their work. Their archival records offer numerous recipes for producing colored surfaces on iron, silver, copper, gold, and alloys. Some of the most striking works made by Tiffany & Co. in the nineteenth century were crafted from copper that had been patinated bright red. The primary method Tiffany & Co. used to create the red patina was to immerse copper in a heated solution containing copper sulfate and/or copper acetate.

Left: Tiffany & Co. (American, 1837–present). Vase, 1879. Silver, copper, gold, and silver-copper-zinc alloy, 11 1/2 x 6 3/8 in. (29.2 x 16.2 cm). The Metropolitan Museum of Art, New York, Sansbury-Mills Fund, 2019 (2019.44); Right: Technical Manual, p. 132. Gorham Company Archive, John Hay Library, Brown University, Providence, Rhode Island

Many of the patination solutions they developed could create different colored patinas on different metals, which allowed Tiffany to use a single solution to create multi-colored objects. For example, the solution described above used to patinate copper red could be used to patinate copper platinum alloys black and brass olive.

The patination solution is made by gently grinding and measuring out copper sulfate and ammonium chloride. The copper sulfate is added to a beaker of distilled water, and the ammonium chloride is set aside to be used later.

Because any impurity left on the surface can interfere with the patination solution, the surface of the copper to be colored is lightly polished with pumice to remove dirt, grime, fingerprints, or oxides that may be present on the surface. Residue from polishing is rinsed off with distilled water. As a final cleaning step, the object is rinsed in dilute phosphoric acid.

The copper sulfate solution is placed under a fume hood, a ventilation device that protects the artisan from exposure to toxic fumes, and heated until boiling. Then the copper object is suspended in the solution and left for fifteen minutes. After that time has elapsed, the object is transferred to a beaker filled with hot water. The hot water keeps the object from cooling off while the ammonium chloride, measured out earlier, is added to the copper sulfate solution. The object is placed back in the patinating solution and then left to boil for another ten minutes. Once the desired color is achieved, the copper object is removed from the solution, rinsed with distilled water, and wiped dry with acetone.

The final color can vary depending on the exact proportions of the components of the solution, the length of time the metal is submerged, and the composition of the metal itself.

Through meticulous practice and expertise, artisans could achieve precisely the color and tone they sought. Four samples of copper, each submerged in the solution for varying durations of time, demonstrate a range of colors from cherry to brick red and rich plum.