Read about how Tiffany & Co. employed the metalworking technique of damascening with illustrative artworks and process demonstrations, or watch the video below.

Damascening is a decorative metalworking technique in which a soft metal, often gold or silver, is mechanically inlaid into a harder metal like iron or steel without heat or solder. This can be done by hammering the softer metal into a recessed area of the harder material, using the lip around the edge of the recess to help hold the inlay in place. Another approach is to cross-hatch the surface of the harder metal, creating the rough surface with tooth that can hold a soft foil or wire.

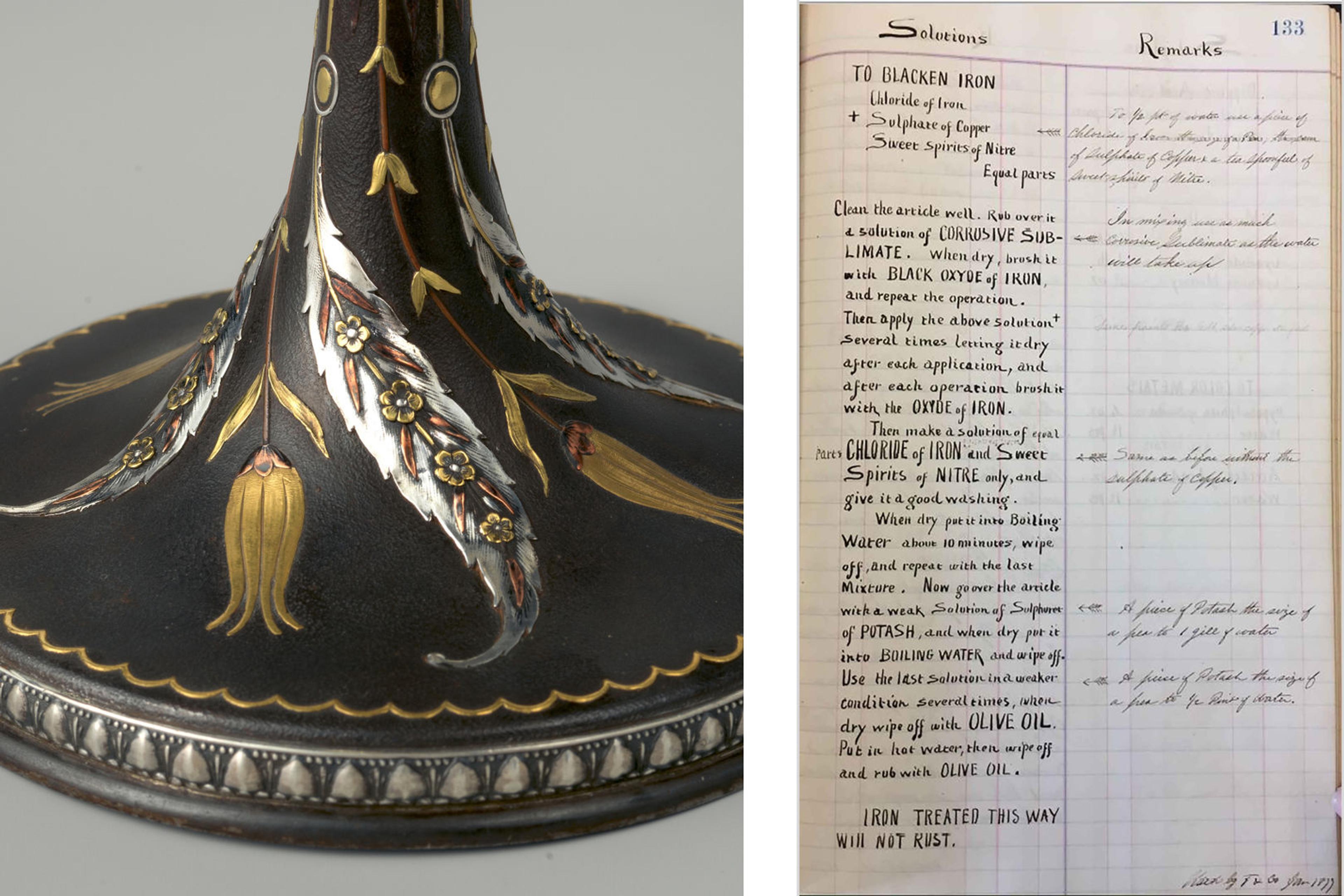

To heighten the differences between the mixed metals after damascening is completed, the steel substrate often will be patinated black. The black provides a strong contrast to polished gold, silver and copper.

According to the firm’s archival records, Tiffany & Co. used a patination solution composed of “chloride of iron, sulphate of copper, and sweet spirits of nitre” to create a black patina on steel.

Left: Tiffany & Co. (American, 1837–present). Candlestick (detail), 1878. Iron, silver, gold, and copper, 7 1/2 × 4 3/8 in. (19.1 × 11 cm). The Metropolitan Museum of Art, New York, Purchase, Sansbury-Mills Fund and Spencer Marks Gift, 2018 (2018.121.1a, b); Right: Tiffany & Co., Technical Manual, p. 133. Gorham Company Archive, John Hay Library, Brown University, Providence, Rhode Island

This technique requires two hands free for working, so the object to be damascened needs to be secured. In the example below, a steel coupon (a small piece of metal) has been seated into a heated, soft mixture of asphaltum and resin in a “pitch pot,” a rounded metal container. Once the pitch has cooled and hardened, the metal surface can be worked. The pitch mixture provides a hard-yet-malleable surface to work against that is pliable enough that the metal will be deformed when struck with a tool, rather than crushed. The pitch pot can be rotated and tilted, allowing the craftsperson to easily adjust the positioning of the object.

Next, the surface of the steel is thoroughly cleaned to remove any dirt, dust, or grime that might interfere with setting the gold foil inlay.

A chasing hammer and a steel chisel are used to texture the areas on the surface of the steel where the foil will be placed. The chasing hammer used below has a wide head and springy handle that allows it to move quickly across the surface of the metal. By lightly tapping the end of the steel chisel, the craftsperson creates a series of fine hatch marks in the coupon. A crosshatched surface is created by turning the pot and continuing to work.

The gold foil inlay is brushed clean and positioned on the cross-hatched surface.

The foil is pushed into the cross-hatching using a wooden tool with a flat surface. A wooden tool is hard enough to force the gold foil into the ridges of the cross-hatching without flattening them out. Next, a copper tool with a flat bottom is used to start flattening out the steel to hold the gold foil in place.

A steel burnisher—a polishing tool with a smooth, slightly convex head—is then used to flatten out the areas of cross-hatching around the inlaid gold.

A solution of hydrogen peroxide, salt, and white vinegar is applied to the surface of the damascened steel around the gold foil inlay. This solution will cause an oxidation reaction to occur on the surface, forming a thin layer of rust.

Patination is a separate but related process by which exposure of a metal surface to air and humidity creates a layer of metal oxides. One way to patinate steel is to take advantage of a spontaneous reaction that occurs between iron oxide, rust, and tannic acid, a natural compound in many plant leaves and galls (fungal growths that form on plants).

When the coupon is then dipped into a beaker of freshly brewed green tea, the rust on the surface of the coupon will react almost immediately with the tannic acid in the tea to form the black precipitate ferrous tannate.