Major Bashford Dean, ca. 1917. The Metropolitan Museum of Art, Arms and Armor Departmental Archives

«The industrialization and mechanization of war in the early twentieth century—which meant an increased use of artillery, tanks, and machine guns, and the advent of trench warfare—resulted in an unprecedented number of killed and wounded soldiers right from the outset of World War I in 1914. The large number of head wounds suffered by combatants soon made it apparent that metal helmets, though long out of use, were absolutely necessary on the modern battlefield and that other forms of armor also should be explored. Shortly after the United States entered the war in 1917, the government turned to Dr. Bashford Dean, curator of arms and armor at the Metropolitan Museum, to address the situation.»

Dean was soon commissioned as a Major of Ordnance in charge of the Armor Unit and also was made Chairman of the Committee on Helmets and Body Armor of the National Research Council. Working from his knowledge of historical armor, Dean made a thorough study of armor used to defend against firearms from the Renaissance to his own time and applied that information to contemporary battlefield conditions of the Great War. Then, in conjunction with the Museum's armorer, Daniel Tachaux, and other members of his staff, Dean produced a series of prototype helmets and various forms of body armor designed to protect US troops. In addition to his museum duties and other commitments during 1917 and 1918, Dean traveled frequently to Washington for meetings and made trips to London and Paris to confer with members of the general staff of the British and French military.

A German soldier, wearing the iconic German helmet known as the Stahlhelm, lights the cigarette of a wounded British soldier at a British field hospital during the Battle of Épehy, 1918 (Lt. Thomas K. Aitken, British Army Photographer, Imperial War Museums) © IWM (Q11538) www.iwm.org.uk

Dean's principal challenge was to devise a helmet that would provide superior protection while being light and comfortable enough to wear for extended periods of time, and which could be mass produced efficiently and economically. By 1916, Germany had developed a helmet—the iconic Stahlhelm (literally "steel helmet)—that met all these requirements, so Dean faced the additional challenge of coming up with an equally effective design that would not be confused with German helmets on the battlefield. American soldiers at the time were wearing the standard British Brodie helmet, patented in 1915 and soon nicknamed the "tin hat" due to its shallow bowl and broad, straight brim. While not nearly as effective as the German helmet, it provided adequate protection to the top of the head and, due to its shallow profile, had the advantage of being easy to manufacture.

Daniel Tachaux (1857–1928). American Helmet Model No. 2, 1917. New York, New York. Steel, pressed paper or cardboard. The Metropolitan Museum of Art, New York, Purchase, Gift of Bashford Dean, by exchange, 2013 (2013.581a, b)

Designed in June 1917, the American Helmet Model No. 2 was Dean's first fully realized attempt to improve upon the existing German and British types. This hand-forged example is one of only a few nonballistic prototypes that Daniel Tachaux made in the Museum's Armor Shop as models for prospective manufacturers. Its deeply drawn-down bowl was intended to give much more coverage to the back and sides of the head than the British helmet without impeding movement, vision, or breathing. Although difficult to manufacture because of the depth of the bowl, approximately two thousand examples were produced by Ford Motor Company in the fall of 1918.

Hale & Kilburn Company (American, 1873–1933). American Helmet Model No. 5, 1918. Philadelphia, Pennsylvania. Steel, paint, leather, textile, string. The Metropolitan Museum of Art, New York, Purchase, Gift of Bashford Dean, by exchange, 2013 (2013.582)

Dean developed American Helmet Model No. 5 in an effort to combine the protective properties of Model 2 with the ease of manufacture of the Brodie helmet. With this helmet he felt he had met or exceeded all of the goals of improved protection, wearability, and practicality of production. While less deep than Model 2, its bowl still gave excellent coverage to the back and sides of the head, was lightweight—only 2 lbs. 8 oz. (1130 g)—and was not overly complex to manufacture. Much to Dean's disappointment, the design was rejected because field commanders felt it was both not different enough from the British helmet and too similar to the German helmet.

W. H. Mullins Co. (American, 1872–1974). American Helmet Model No. 7, Sentinel's Helmet, 1918. Salem, Ohio. Steel, leather, textile, paint. The Metropolitan Museum of Art, New York, Purchase, Gift of Helmut Nickel, by exchange, 2013 (2013.583)

Weighing 13 lbs. 12.6 oz. (6254 g) and highly specialized in its design and intent, the American Helmet Model No. 7, Sentinel's Helmet, was meant to be worn only for short periods of time in exposed or forward positions, where heavy enemy fire was expected. Its construction was based directly on that of the Italian armet (see example), a type of helmet popular during the late fifteenth century. Several examples were manufactured and sent to France for field testing, but despite its proven ability to resist rifle fire, the helmet was rejected due to its weight.

Ford Motor Company (American, founded 1903). American Helmet Model No. 8, 1918. Steel, leather, felt, canvas, bronze, pigment, sawdust. The Metropolitan Museum of Art, New York, Purchase, Rogers Fund by exchange, 2012 (2012.473)

Dean believed that his American Helmet Model No. 8 was the most successful in providing overall protection to the face and head, while still allowing for good visibility and mobility. In addition, it was fairly light at 3 lbs. 10.5 oz. (1660 g). Dean refined the design to ensure that the helmet was well balanced and could be worn comfortably with its visor up or down. Ford Motor Company produced about 1,300 examples in die-stamped ballistic metal in November 1918, but the helmet saw only limited field testing before the war ended.

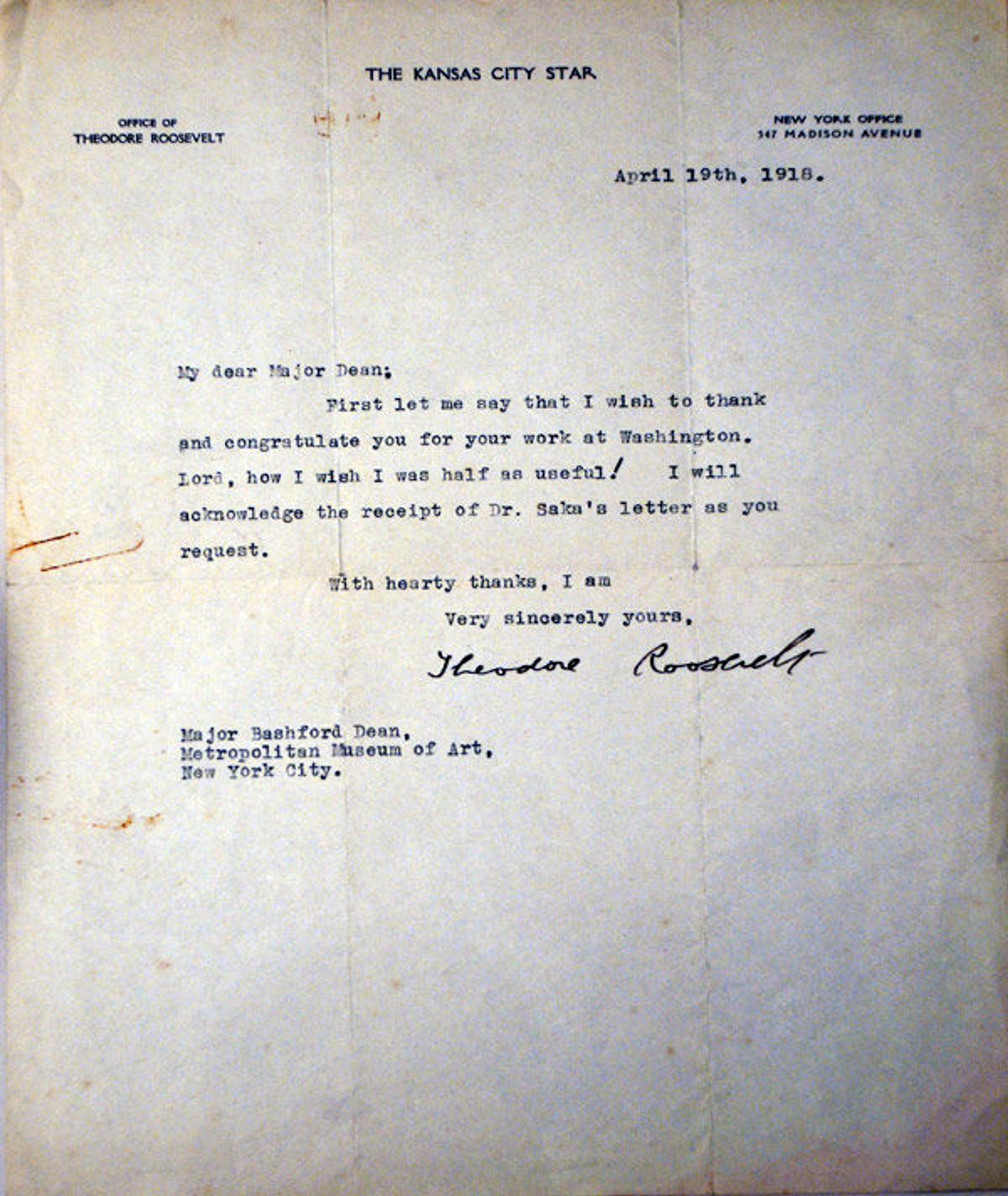

Dean and his team also created fully functional protection for the neck, torso, shoulders, arms, and legs—in effect, the first full body armor since the seventeenth century. Nearly forgotten by all but specialists and historians these days, Dean's war work was justifiably appreciated and praised at the time. Former President Theodore Roosevelt (1858–1919) wrote to Dean in 1918 to express his personal admiration for Dean's contributions to the war effort, saying "Lord, how I wish I was half as useful!"

President Theodore Roosevelt to Bashford Dean, April 19, 1918. The Metropolitan Museum of Art, Arms and Armor Departmental Archives, Gift of Dean K. Boorman, 2011

After the war, Dean compiled a detailed record of his research and its results, which was published in 1920 as the book Helmets and Body Armor in Modern Warfare. Carl Otto von Kienbusch (1884–1976), Dean's protégé and a fledgling arms and armor collector, was commissioned as a lieutenant and assigned to assist Dean during the war and subsequently in the preparation of the book. In several of the book's illustrations, Kienbusch can be seen modeling prototypes, as can Raymond Bartel (died 1949), an armorer from France who Dean had brought to New York in 1914 to work at the Museum. Kienbusch later went on to become the leading private arms and armor collector in America and eventually bequeathed his collection to the Philadelphia Museum of Art, where it can be seen today.

Although none of Dean's designs was officially adopted before the war ended in 1918, his work provided an important foundation for the subsequent development of protective gear worn by American soldiers in all subsequent conflicts. His book on the subject is still considered a classic by contemporary designers of military armor. Following in Dean's footsteps, Stephen Grancsay (1897–1980), who succeeded Dean as curator in 1929, provided the United States government with designs for helmets, body armor, and other equipment during World War II and the Korean War.

Leonard Heinrich making the Model T21 E2 helmet prototype in the Armor Shop, Metropolitan Museum of Art, July 13, 1945. The Metropolitan Museum of Art, Arms and Armor Departmental Archives

Leonard Heinrich (1900–1966), the Museum's armorer from 1924 to 1964, made prototype helmets for the war effort with Grancsay, just as Tachaux had done with Dean a generation before. The reintroduction of extensive, form-fitting body armor was a radical idea when Dean designed his prototypes in 1917, but it is now readily accepted as a vital part of a soldier's battle gear. Dean's pioneering efforts helped pave the way for this life-saving change in attitudes toward the use of modern body armor.